Hippo Filter System

FIRST FOR VERSATILITY

HIPPO FILTER SYSTEM

- Full-flow filtration system

- Bypass-filtration system

- Water Based Fluids

- Process Fluids

- Heating Oils

- Turbine Oils

- Bio-ethanol

- Kerosene

- Diesel

- Petrol

- Oils

Ferrocare

Tel No: 91 22 2683 0655

Email: info@ferrocare.com

Web: www.ferrocare.com

23-25 Gulmohar Indl Est,

Salunke Vihar Road

Wanawadi

Pune

411 040

India

Why Should I use a Hippo Filter?

Why do I need a Hippo Filter?

Standard in-line filters mostly filter down to 20 micron efficiency. The most harmful contaminants in oil are sub 5 micron particles, these are also the most abrasive. The Hippo filter is capable of removing harmful solid contaminants down to 3 micron.

Why should I use a Hippo Filter?

FACT: Effective filtration will extend the life of your machinery and maintain oil cleanliness.

How often do you change your Oil?

It is a well known fact that oil and fuel cleanliness is critical. It is not uncommon for large machines to dispose of oil on a monthly basis. By fitting a Hippo filter, you will extend the lifetime of your oil.

Extend oil life up to 10 times:

By fitting a Hippo filter, you can ensure your oil (lubricating, hydraulic or gear oil) remains clean and dry. This will ensure that the oil remains in excellent condition for up to 10 times longer.

Simple Installation:

- The Hippo filter can be fitted quickly and simply by approved mechanics

- Water and Solid Particulate Removal

- The Hippo Filters high performance cartridges allow for the removal of ultra-fine particles and debris, thereby immediately reducing the risk of contamination-induced damage to parts and machinery.

The Hippo series can be used to enhance the life and performance of other, more expensive system filters. The wear and tear of hoses and fittings is also greatly reduced due to the effective removal of harmful particulate.

With today’s machinery operating under increasingly fine tolerances, the removal of particulate and moisture down to acceptable levels is paramount.

As the Hippo system effectively removes water from the oil/fuel, the risk of fluid degradation is significantly reduced along with inevitable associated down-stream problems.

Features and Benefits:

- Eliminates water from oil using cellulose elements

- Eliminates oil from water using polyproylene elements

- Does not remove additive packages

- Extends oil drain intervals

- Increases service intervals

- Provides continuous protection

- Environmentally friendly

- Reduces machine downtime

- Removes dirt and solid contaminants down to NAS 5/ISO 14/9 or better

1

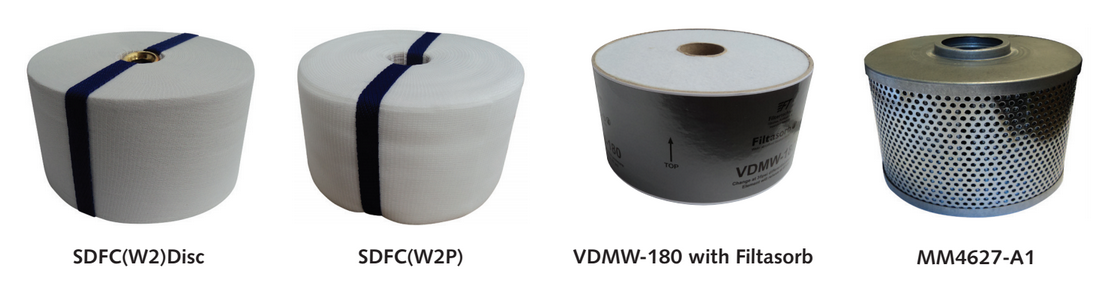

Cartridges Available

| Compatibility | Element Type |

Achievable Cleanliness Code |

Retention | Height mm |

Diameter mm |

Weightgrm | Flow rate recommendation |

|

|---|---|---|---|---|---|---|---|---|

| Solids grm | Water ml | |||||||

| Oils & fuels | SDFC(W2) | ISO 4406 14/9NAS class 5 |

Up to 2200 | 750 | 112 | 180 | 600g ±5% |

1-10 l/min per cartridge |

| Water glycols | SDFC(W2P) | 30 micron nomimal | Up to 2200 | n/a | 112 | 180 | 600g ±5% |

1-10 l/min per cartridge |

| Oils &fuels | VDMW-180 with Filtasorb |

20 micron nomimal | Up to 1800 | 800 | 112 | 180 | 500g ±5% |

3 l/min per cartridge |

| Oils & fuels | MM4627A1 | 19/17/14 -18/16/1310 micron absolute NAS 7 |

Up to 1200 | n/a | 112 | 180 | 800g ±5% |

22 l/min per cartridge |

| Operating Temperature The cartridge will operate within the operating specification of engine, hydraulic and gearbox oils –10 to +120°C. | ||||||||

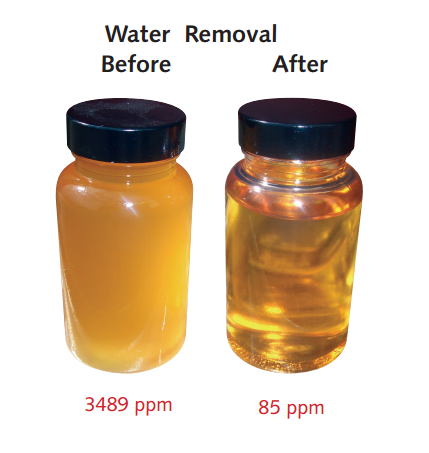

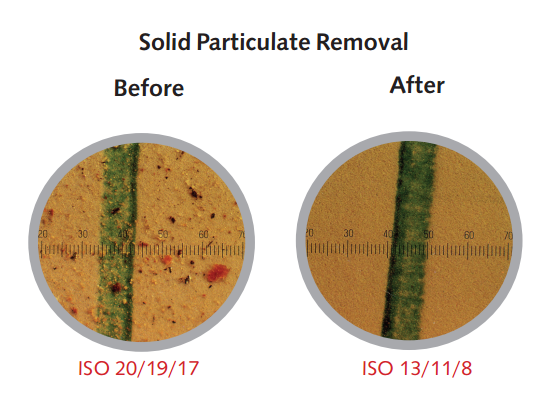

The results speak for themselves:

The fluid samples and patch slides below demonstrate the remarkable filtration capability of the Hippo series of filtration systems.

2

Hippo Product Overview

|

Hippo filter housing |

• Water and particulate removal (depending on element) • 1-10 L/M (depending on fluid viscosity) • 10 bar maximum pressure• 120oc maximum temperature • 3/8” BSP (F) or 1/2” connections BSP (F) * Magnet option to remove metal particulate |

| Order code: FTP180 | For element code please see page 2 |

|

|

|

|

Hippo filter housing with mounting |

• Water and particulate removal (depending on element) • 1-10 L/M (depending on fluid viscosity) • 10 bar maximum pressure • 120oc maximum temperature • 3/8” BSP (F) or 1/2” connections BSP (F) • Complete with a mounting bracket * Magnet option to remove metal particulate |

| Order code: FTP180B | For element code please see page 2 |

|

|

|

|

Hippo filters mounted onto nylon manifold |

• 2 x Hippo mounted on a manifold block • Water and particulate removal (depending on element) • 1-16 L/M (depending on fluid viscosity) • 10 bar maximum pressure • 120oc maximum temperature • 3/4” BSP (M) connections * Magnet option to remove metal particulate |

| Order code: FTP180-2 | For element code please see page 2 |

|

|

|

| • Off-line Hippo System • Up to 20 L/M at 4 bar (depending on fluid viscosity) • 10 bar maximum pressure * • Gauge to show when filters blocked • Water and particulate removal (depending on element) • 120oc maximum temperature * Various valve arrangements can be incorporated into the inlet to allow for high pressures * Magnet option to remove metal particulate |

|

| Order code: FTP180 | For element code please see page 2 |

|

|

|

|

Oil or Fuel Polishing System |

• Static or portable • 10 L/M Maximum flow rate (depending on fluid viscosity) • Water and particulate removal • Removes up to 2Kg of particulate and 0.7 litres of water per element • Pressure gauge filter blockage indicator • 240/110v Options • 3 meter suction and return line hoses • 1 meter lances on hoses |

| ORDER CODE: BD5000 | For element code please see page 2 |

|

|

|

|

Portable Oil or Fuel Polishing System |

• Portable filtration cart (upright sack truck) • 10 L/M Maximum flow rate (depending on fluid viscosity) • Water and particulate removal • Removes up to 2Kg of particulate and 0.7 litres of water per element • Pressure gauge filter blockage indicator • 240/110v Options • 3 meter suction and return line hoses • 1 meter lances on hoses * Unit can be fitted with a water monitor and a particle counter |

| Order code: FTP180 | For element code please see page 2 |

|

|

|

|

Hippo Buggy |

• Rugged portable 6 pot buggy • 240/110 VAC 50/60 Hz operation/air drive • 22 L/M Maximum flow rate • Fitted with 6 x super duty hippo pots • 10 bar maximum pressure • Removes up to 2Kg of particulate and 0.7 litres of water per element • Pressure gauge filter blockage indicator • 1” Inlet/ outlet • Sample points fitted • Particle Counter (PC9001) with software for contamination trending • 7 day timer with 4 x daily on/off features (optional) |

| Order code: FTP180 | For element code please see page 2 |

|

|

|

3